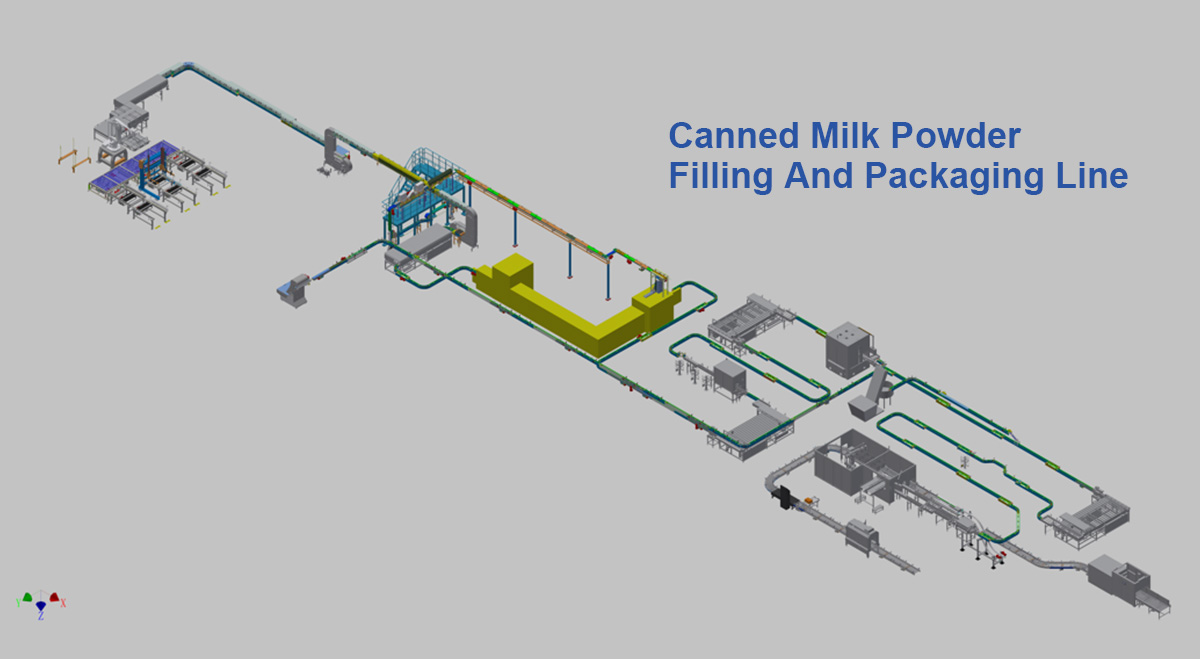

U-PACK is highly experienced in building high speed production and packaging line for canned milk powder.

What we provide for the overall solution includes the sections as empty can depalletizer, empty can cleaning machine, UV sterilization tunnel for empty cans, can ends feeding system and UV sterilization tunnel, filler, seamer, Lazer coder, X-ray machine, fliptop capper, case packer, palletizer and automated warehousing system.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis. We have robotic and mechanical depalletizer for empty cans to meet different production requirement. The robotic depalletizer could reach the function of picking & placing the whole layer cans and paper sheet between the layers by the specialized design of fixture.

It could combine with the laser ranging technology for confirming the distance between the fixture and the empty cans in real-time to improve the depalletizing efficiency.

The empty cans cleaning machine adopts advanced flipping, blowing and control technology to ensure that there are no small iron particles or dust inside the cans.

It includes the parts of can flipping, demagnetization, negtive ion air blowing, dust suction , can conveying and magnetic vertical lifting.

This equipment is the preferred sterilization equipment for empty cans entering sterile workshops, with the following characteristics:

1) High intensity ultraviolet disinfection lamp of German "Heraeus"

2) Anti burst design of lamp tubes

3)Anti collision and detachment design of lamp tubes

4) Unique cooling system

5) Reminder on the service life of lamp tubes

The can ends conveying system consists of can ends feeding device, can ends elevating device, can ends sterilization tunnel and can ends conveyor.

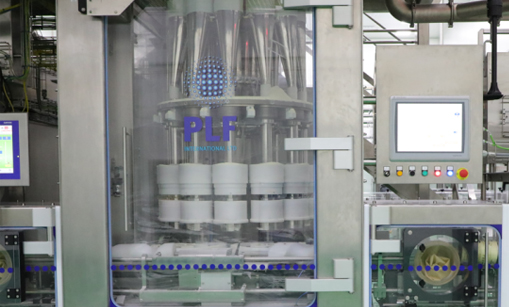

In-line Vacuum Filler is designed to specifically handle a wide range of milk based nutritional powders including infant formula and specialized medical nutrition at speeds up to 180cpm.

Compared to auger filling systems, the vacuum filling system has no moving parts in contact with the product, which eliminates any risk of product contamination, as well as the possibility of powder breakdown during filling.

The Vacuum Gassing Seaming system is designed to provide a next level solution for the modified atmosphere packaging of infant formula and special medical formula powders.

The vacuum, gassing and seaming process separates the operations of a traditional vacuum gassing seamer into two distinct stages. Firstly, air is evacuated from the filled can and replaced with an inert N2/CO2 gas mix before moving onto the single seaming station. All operations are carried out in a low oxygen environment to ensure very low levels of RO are achieved in the sealed can.

It includes servo-driven screwing unit for cans feeding, laser printing, code verification and rejection unit.

Features

1)Compact design for integrating multi-functions on one machine

2)Quickly change over for various size products.

3)Servo-driven to ensure better stability during high-speed transportation.

Meet the challenge of detecting foreign objects anywhere in cans and bottles with the Sideshoot X-Ray Inspection System. This high speed, high performance horizontal x-ray beam (back to front) system provides single beam x-ray inspection for tall, upright packages and includes software specifically tailored to detect objects in all regions of cans and bottles. The system is designed to use an existing conveyor to reduce cost and floor space. The system meets HACCP requirements and can be upgraded to meet IP69K washdown specifications.

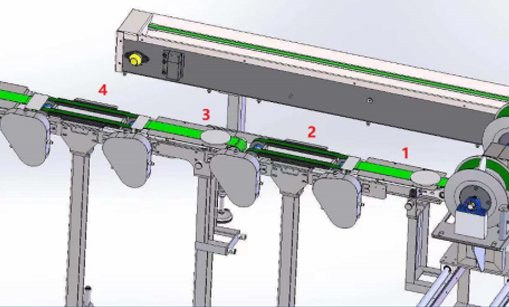

Each can is holded by magnetic holder which is driven by servo motors seperately. The visual system detects the relative position between the confirmed point on the can and the cover, transmits the information to the PLC, and then the can bottom holder rotates the can to reach the correct position for pressing high cover according to the requirement on the URS document.

The robotic case packer is specially designed for case packaging for canned milk powder with the following features:

1) The fixture could pick and place 4 groups cans per cycle which improve the capacity greatly.

2) "ABB" or "KUKA" robot to ensure the stable performance of the system.

3) It could fulfill placing cans and partitions into the case on one machine

The palletizing system consists of robotic palletizer, pallet supplying machine, pattern forming section and pallet conveyor. It has the following advantages.

1) Space saving

2) Flexible for various palletizing requirements

3) Picking cases or pallets by one specially designed fixture

We provide one-stop automated warehousing solution which could satisfy the demand of all links in the supply chain, such as receiving ,warehousing, replensishment, picking,packaging and delivery.

The automated warehousing system includes the following parts:

1) Racking system

2) Chain conveying and roller conveying system

3) Stacker crane

4) PLC control system

5) WMS and WCS

Our main products include automatic case packer, wraparound case packer, blister packaging machine, cartoner, palletizer, automated warehousing system, AS & RS, etc.