Pharmaceutical

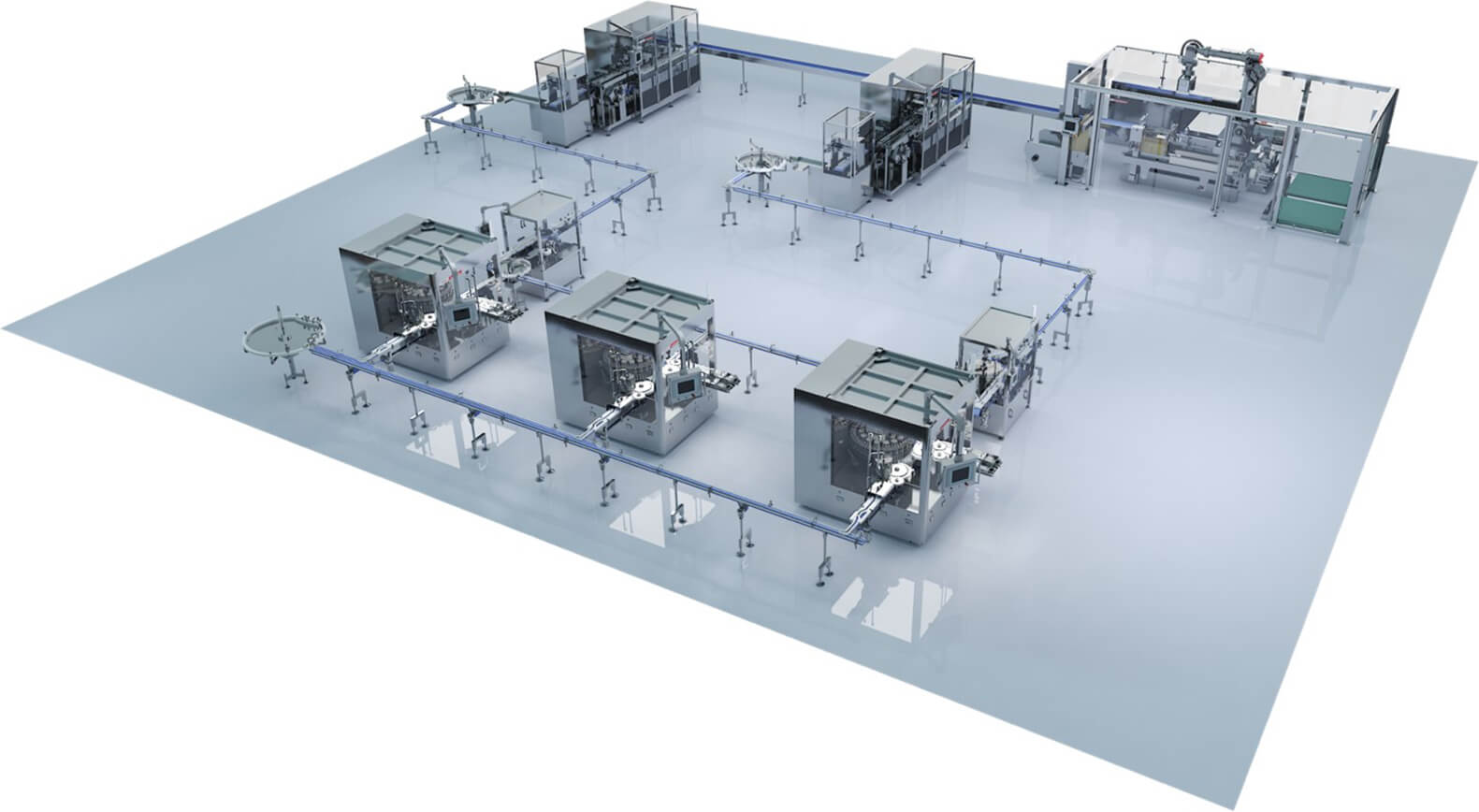

With the rapid development of pharmaceutical technology, the trend of large-scale manufacturing and mass production of drugs is becoming more and more obvious, which puts forward higher requirements for pharmaceutical machinery equipment, especially for post pharmaceutical packaging equipment. For injection products such as penicillin bottle, ampoule bottle, oral liquid bottle, etc., the equipment maintains stability under high-speed operation conditions, meets the compatibility of multiple kinds of packaging, is suitable for rapid switching of multiple kinds of products, and achieves the requirements of overall packaging automation and traceability, which becomes the difficulty of industry development, and also the opportunity to improve the performance and technology of packaging equipment.

U-PACK packaging R & D team combines domestic and international development trends, introduces foreign advanced design concepts, and through U-PACK manufacturing platform, strives to build a high-quality, high-performance, highly automated drug packaging system to meet the increasing packaging needs of domestic and foreign customers.