| Index | Parameters | Unit | |

| Basic parameters | Size | 1137 (L) 819 (W)325 (H) | mm |

| Weight | 300 | kg | |

| Max. lift height | 60 | mm | |

| Rated load | 1000 | kg | |

| Operation parameters | Rated running speed(no-load) | 1500 | mm/s |

| Rated running speed(rated load) | 1200 | mm/s | |

| Rated acceleration(no-load) | 400 | mm/s² | |

| Rated acceleration(rated load) | 300 | mm/s² | |

| Positioning accuracy | ±10 | mm | |

| Stop angle accuracy | ±1 | degree | |

| Stop position accuracy | ±10 | mm | |

| Battery (lithium iron phosphate) | Rated voltage | 48 | V |

| Battery capacity | 30 | Ah | |

| Charging cycles | 1500 | time | |

| Working time under rated working condition | 8 | h | |

| Charging time | Charging time after full discharging<=1.5 | h | |

| Safety performance | Laser obstacle avoidance | Obstacle avoidance with front laser | |

| Infrared obstacle avoidance | Obstacle avoidance with rear infrared | ||

| Magnetic stripe detection | Front / rear magnetic stripe detection | ||

| Emergency stop button | Front/rear emergency stop button | ||

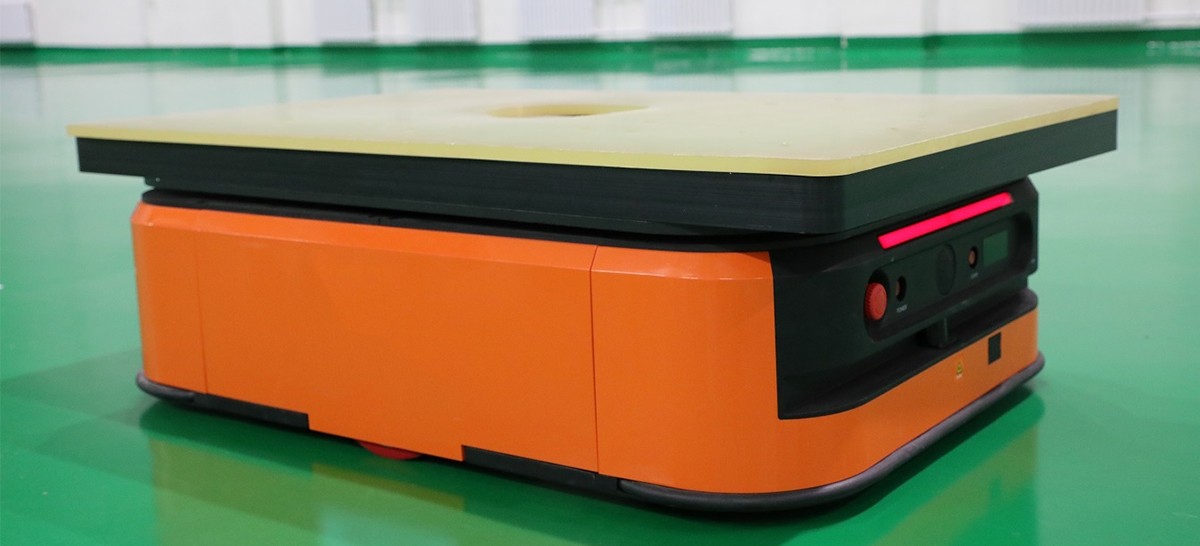

(*)This product adopts independent shallow charge and shallow discharge power management mode.

Employs technologies such as inertial navigation and visual navigation to achieve precise autonomous positioning.

Features a two-wheel differential drive for smooth and flexible motion control, including forward, backward, and rotational movement.

Incorporates intelligent power management with multi-level thresholds. It autonomously docks for charging at low power and resumes operations upon completion.

The system ensures operational safety with multi-layer protection, including long-range and short-range front detection, collision sensors on both the front and rear sides, and emergency stop buttons at the front and rear.

Capable of lifting, transporting, rotating, and lowering heavy loads with a capacity of up to 1,000 kg.

Provides clear status indication through a two-color indicator and digital tube, displaying information such as power level and system status.

Supports WiFi communication with seamless roaming, enabling uninterrupted operation throughout the network coverage area.

Suitable for different sizes of cartons, bins and standardized unit goods.

2 or 4 direction, single depth or double depth are available

High speed, precise positioning

| No. | Items | Specifications | ||

| 1 | Shuttle weight | < 100KG | ||

| 2 | Speed of X-axis | Loaded > 3m/s | No-load > 5m/s | acceleration 2m/s² |

| 3 | Speed of Y-axis | >2m/s | acceleration 0.5m/s2 | |

| 4 | Maximum loading | <50KG | ||

| 5 | High speed lifter for shuttle | Loaded >3m/s | No-load > 4m/s | acceleration 2m/s² |

| 6 | High speed lifter for material bin | >4m/s | acceleration 2m/s² | |

| 7 | Power | Supercapacitor | ||

| 8 | Battery cycle count | 500 thousand times | ||

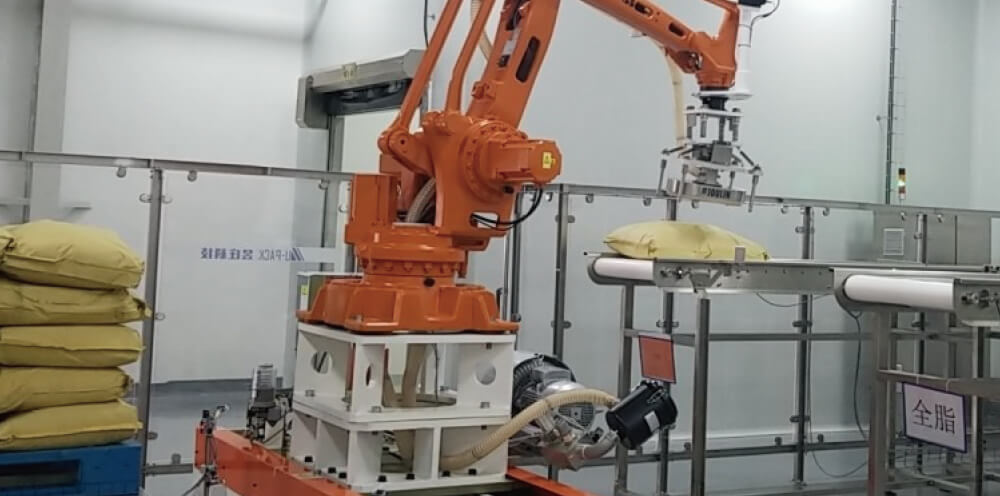

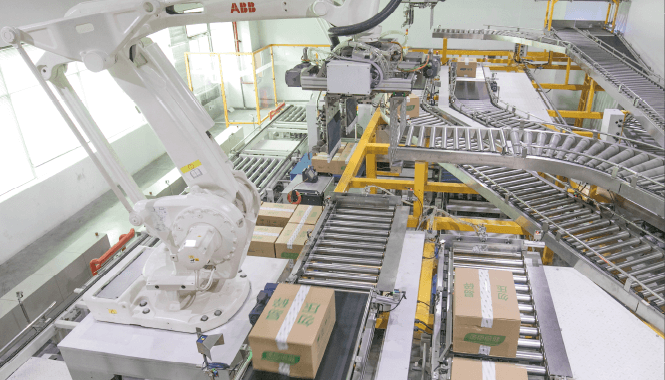

The application of robots in this work greatly reduces the labor intensity of workers and increases the reliability and stability of equipment. By replacing different fixtures, it can be applied in the work of depalletizing and palletizing for different products which increase the flexibility greatly.

The cartons are arranged in a certain order to form a group (layer). The lifter carries the sorting layer up and moves forward to the upper part of the palletizing device, and smoothly places it on the pallets (or the former sorting layer) to form an automatic palletizing. For the high speed palletizing demand, this model can also be customized as a two-channel model.

The equipment can be used for unloading cartons, tins and bags. Different procedures are set up to meet the unloading requirements of different stacking shapes. Different types of fixture are equipped for different products. The optional 3D vision system can meet the unloading requirements of irregular objects (such as large packaging soft bags).