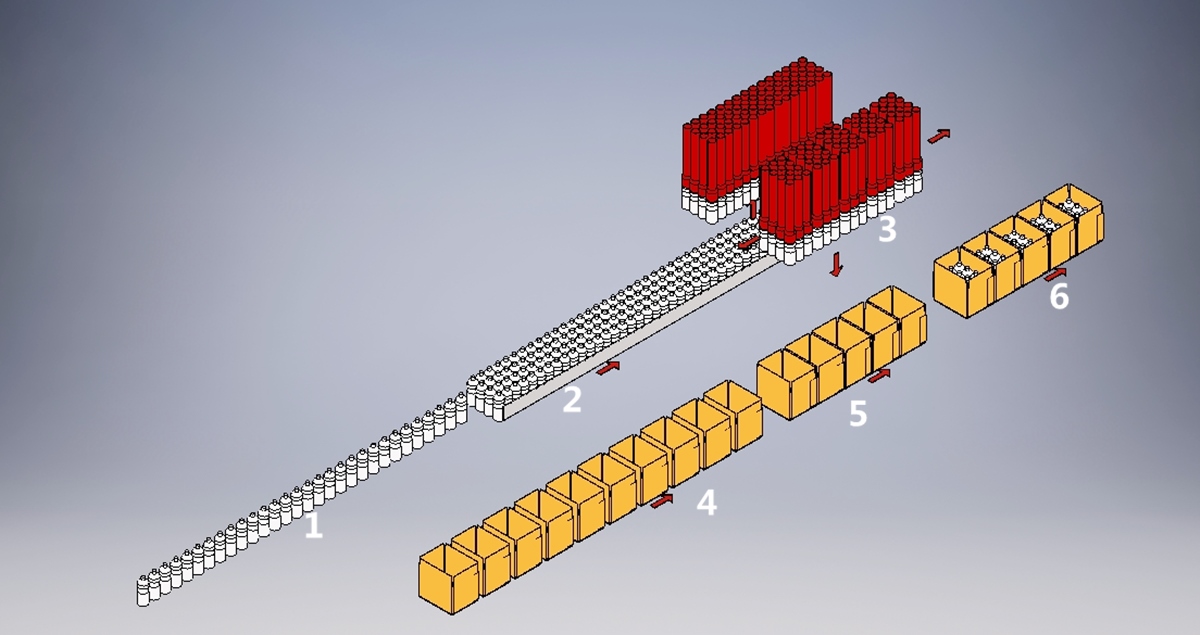

The Mechanical Case Packaging Machine utilizes an air-powered gripper head to pick up and place products. A twin four-bar linkage mechanism then lifts, transports, and lowers the bottles. To maximize productivity, the machine rapidly returns to its starting position when unloaded, minimizing non-productive time. This type of mechanical packer is widely used for packing bottled products into pre-formed cartons.