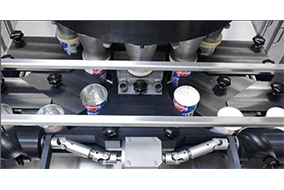

This German OPTIMA original import model features an integrated auger metering system, enabling continuous high-speed and high-precision filling for powdered products.

This German OPTIMA original import model features an integrated auger metering system, enabling continuous high-speed and high-precision filling for powdered products.

Robust design with fully enclosed construction.

Centralized control of filling and dosing systems.

Motorized height adjustment of the filling turret accommodates containers with identical diameters but varying heights.

Dust-free filling is achieved through integrated sealing elements in the filling zone.

Air nozzles on the filling turret prevent product accumulation.

Each container is transported and lifted by dedicated carrier segments that prevent damage.

Precision-machined edges on the filling turret create individual portions.

Vertical vibration applied to container bases ensures thorough product compaction throughout the filling cycle.

Graphical display of machine status.

Integrated troubleshooting and optimization functions.

Memory for 200 recipes (product parameters).

Robust design with enclosed machine body.

Central operation of filling system and dosing system.

Motorized height adjustment of the filing turret for containers with the same diameter but different height.

Dust-free filling is ensured by a sealing element in the filling area.

Air shower on the filling turret to avoid product build-up.

Each container is transported and lifted with a carrier segment which prevents damages on the container.

The cutting edges of the filling ring turret form the individual portions.

A vertical vibration acting on to the container bottom ensures an intensive product compaction during the entire cycle in the filling star wheel.

Graphic visualization of machine states.

Support for fault clearance and machine optimization.

Memory for 200 recipes (product parameters).

Does not match? Click here to provide you with the customized solution

Contact Us