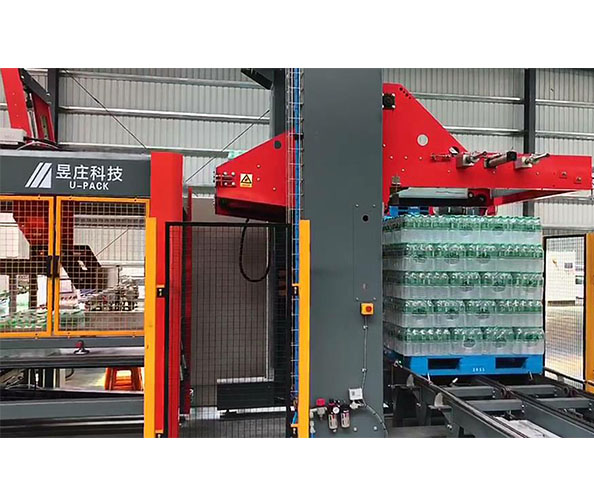

The cartons are arranged into a patterned layer, which the elevator then lifts and transfers over the palletizing unit, placing it gently onto the pallet (or previous layer) to complete the automated palletizing cycle. For higher-speed requirements, this model is also available in a dual-line configuration.