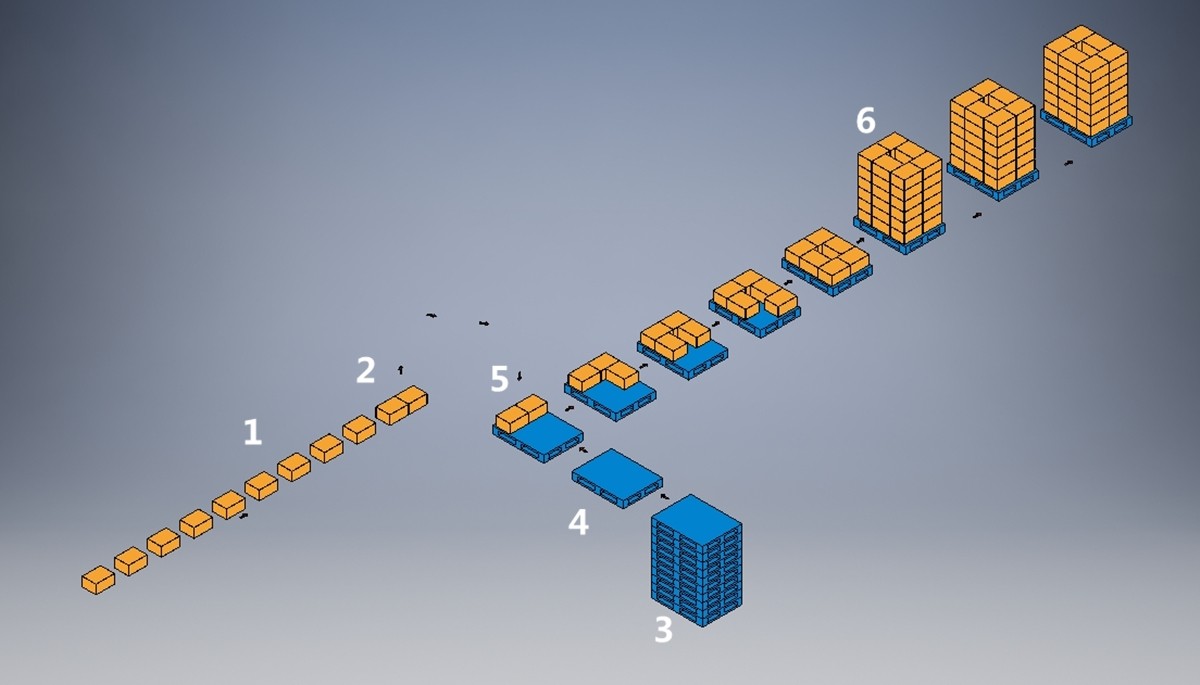

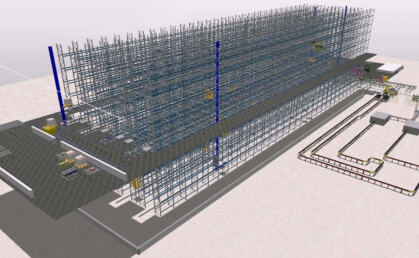

Robotic integration significantly reduces manual labor while enhancing equipment reliability and stability. Quick-change grippers enable adaptation to various depalletizing or palletizing tasks, ensuring operational flexibility.This model handles cases, cans, and pouches for both depalletizing and palletizing operations. Programmable settings accommodate different stack patterns, while product-specific vacuum grippers ensure secure handling. An optional 3D vision system is available for irregular objects.