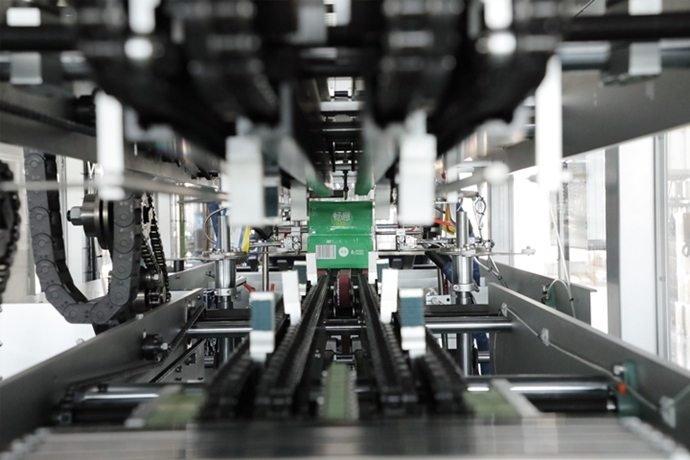

This model employs servo-driven control technology and operates in a continuous motion mode, making it well-suited for high-speed, continuous operation in the beverage, dairy, and food industries.

This model employs servo-driven control technology and operates in a continuous motion mode, making it well-suited for high-speed, continuous operation in the beverage, dairy, and food industries.

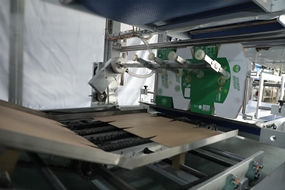

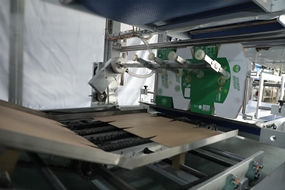

The carton magazine can store up to 800 carton blanks simultaneously.

The system incorporates the advanced ELAU servo control technology.

It offers excellent scalability, networking capabilities, and an open architecture.

The low-impact bottle dividing system minimizes conveyor belt pressure on containers, effectively preventing bottle damage and breakage.

The pusher mechanism is equipped with an automatic clutch and photoelectric stop device to prevent container deformation caused by tipping or jamming during transport.

| Items | Parameters |

| Capacity | Max.45cases/min |

| Closing type | Hot melt glue |

| Carton size range(Unit:mm) | L(260-450) * W(160-300) * H(90-330) |

| Carton blank size range(Unit:mm) | L(580-1450) * W(370-680) |

| Machine size (L*W*H, unit:mm) | L11000×W1800×H2600mm |

| Voltage | 3 phases,380 V 50 Hz |

| Power | 20KW |

| Air comsumption | 800L/Min 6.0 kg/cm2 |

| Carboard requirement | Corrugated paper |

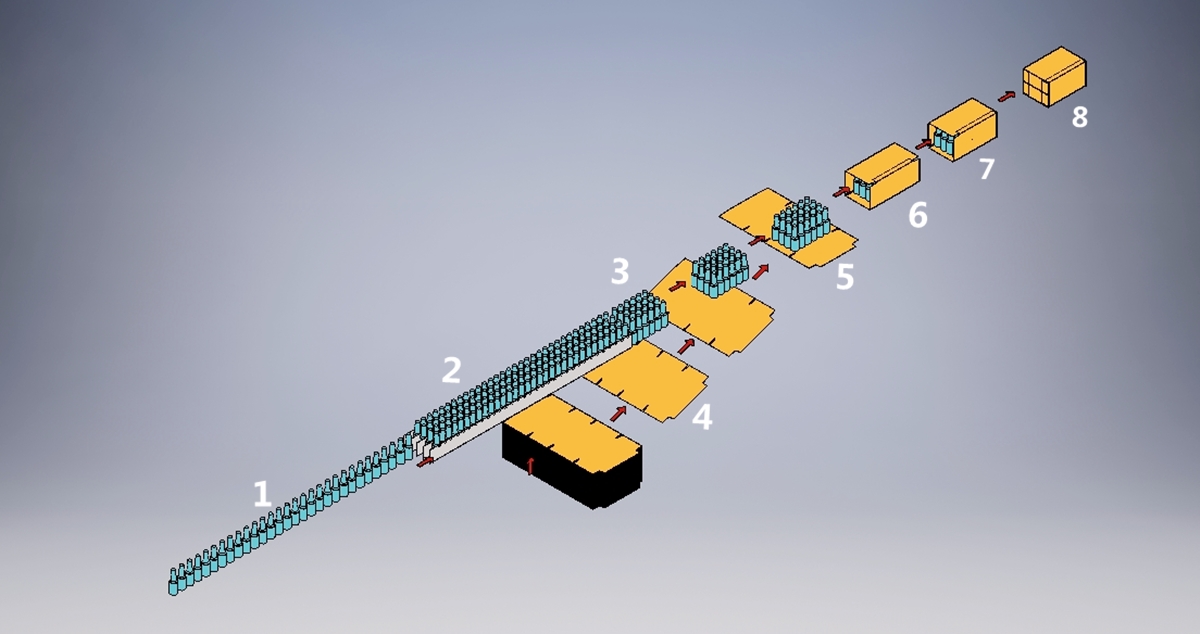

| No. | Working flow | Note |

| 1 | Product infeeding | The infeeding direction depends on the exact requirement. |

2 | Lane dividing | The lanes quantity depends on the exact product pattern for each case. |

| 3 | Product groupping | The product is groupped according to the quantity and pattern of each case. |

| 4 | One sheet case infeeding | The case is picked by vacuum cups and transferred to the loading station. |

| 5 | Product loading | The products are lowered on the case. |

| 6 | Main flap pressing and sealing | By hot melt glue |

| 7 | Side flaps pressing and sealing | By hot melt glue |

The carton magazine can store up to 800 carton blanks simultaneously.

The system incorporates the advanced ELAU servo control technology.

It offers excellent scalability, networking capabilities, and an open architecture.

The low-impact bottle dividing system minimizes conveyor belt pressure on containers, effectively preventing bottle damage and breakage.

The pusher mechanism is equipped with an automatic clutch and photoelectric stop device to prevent container deformation caused by tipping or jamming during transport.

Does not match? Click here to provide you with the customized solution

Contact Us