This machine serves beverage, dairy, and food industries, providing fully automated secondary packaging for bottled and canned products while significantly enhancing production efficiency and reducing packaging costs.

This machine serves beverage, dairy, and food industries, providing fully automated secondary packaging for bottled and canned products while significantly enhancing production efficiency and reducing packaging costs.

The specially designed collating mechanism accommodates various product arrangement patterns within the cases.

The case erecting station features a protective enclosure design that ensures consistent and aesthetically pleasing case formation.

All adjustment points incorporate digital display instrumentation.

Servo-driven mechanisms maintain precise synchronization between all units, ensuring consistently qualified packaging results.

The main frame features a fully enclosed, welded construction that facilitates thorough cleaning and prevents liquid retention.

The electrical appliances are selected from internationally renowned brands, such as Nordson, Festo, Schneider, B+F, etc., to ensure stable and reliable product performance.

Compact construction allows customization for optimal space utilization in specific installation site.

| Items | Parameters |

| Capacity | Max. 35cases/min |

| Closing type | Hot melt glue |

| Carton size range(Unit:mm) | L(260-420)*W(160-300)*H(90-170) |

| Carton blank size range(Unit:mm) | L(580-1450)*W(370-680) |

| Machine size (L*W*H, unit:cm) | L4850*W1680*H1800 |

| Voltage | 220V~440V/50HZ~60HZ |

| Power | 15KW |

| Air comsumption | 1000L/Min 6-8 kg/cm2 |

| Carboard requirement | Corrugated paper |

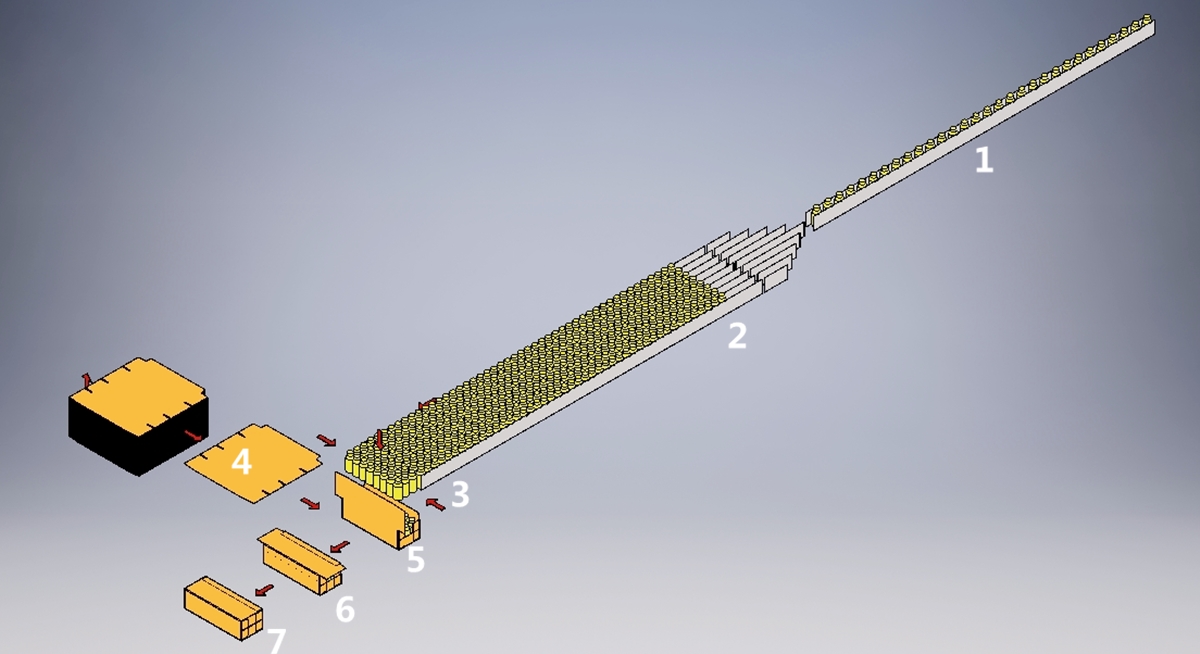

| No. | Working flow | Note |

| 1 | Product infeeding | The infeeding direction depends on the exact requirement. |

2 | Lane dividing | The lanes quantity depends on the exact product pattern for each case. |

| 3 | Product groupping | The product is groupped according to the quantity and pattern of each case. |

| 4 | One sheet case infeeding | The case is picked by vacuum cups and transferred to the loading station. |

| 5 | Product loading | The products are lowered on the case. |

| 6 | Main flap pressing and sealing | By hot melt glue |

| 7 | Side flaps pressing and sealing | By hot melt glue |

| Items | Brand and Supplier |

| PLC | Siemens, Germany |

Touchscreen | Beijer, Sweden |

| Motor | Sew, Germany |

| Servo motor | Siemens, Germany |

| Invertor | Danfoss,Danmark |

| Sensor | P+F, Germany |

| Pneumatic components | FESTO |

| Hot melt glue applicator | Nordson, USA |

| Low voltage electrical parts | Moeller, Germany |

| Machine frame | Stainless steel |

Does not match? Click here to provide you with the customized solution

Contact Us